Can I Use Drywall Primer on Painted Wood?

You’ve decided to give your painted wood surfaces a fresh coat of paint, but you’re unsure whether to use the drywall primer you have on…

You’ve decided to give your painted wood surfaces a fresh coat of paint, but you’re unsure whether to use the drywall primer you have on…

Drywall mud, also known as joint compound, is a crucial component in creating smooth, seamless walls in construction and home improvement projects. It’s used to…

The exterior door threshold is a critical component of your home’s entryway, serving as the first line of defense against the elements. It prevents water,…

Thinset mortar provides the crucial bond between your tiles and the substrate. However, when it comes time to remove or replace tiles, dealing with excess…

When it comes to installing or upgrading an electric stove, one of the most crucial decisions you’ll face is choosing between the 6/2 and 6/3…

Having a sewer cleanout pipe in the middle of my basement always bugged me. It was an unsightly eyesore that ruined the look of the…

I recently decided to install new cabinet pulls in my kitchen, but I didn’t have a template to use. I knew it was possible to…

You got your new hose all ready to have some fun in the sun. But oh no! After giving it a twist, that stupid thing…

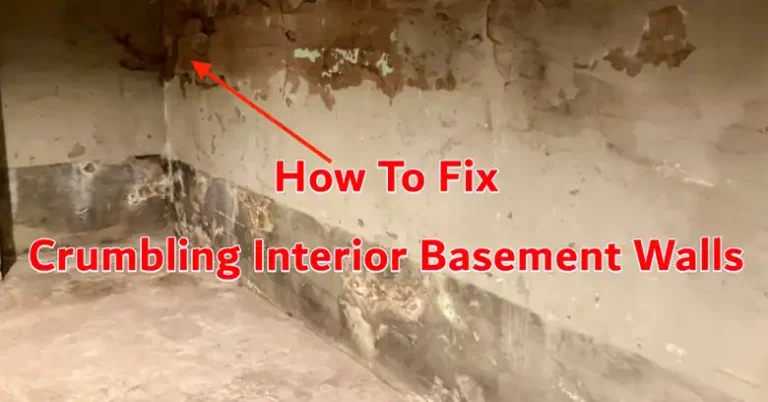

Crumbling interior basement walls can be a homeowner’s nightmare. Whether it’s due to moisture penetration, settling issues, or simply the natural aging process, addressing this…

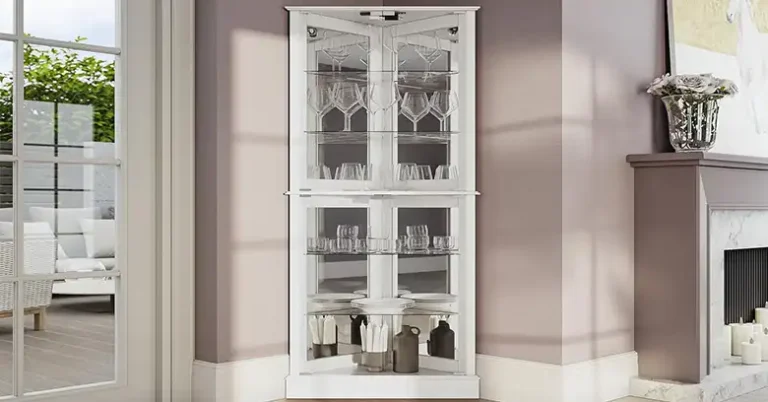

Introducing the BELLEZE Modern Lighted Corner Curio Cabinet – a perfect blend of classic design and contemporary functionality. In a crisp white color, this floor-mounted…